Can't find what you're looking for? Contact us

For better functionality and user experience, Victrex.com uses cookies which can be disabled at any point by adjusting your browsers settings. By using this website you consent to our use of these cookies. Please view our Cookie policy for more information

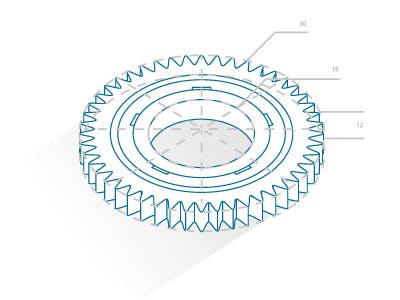

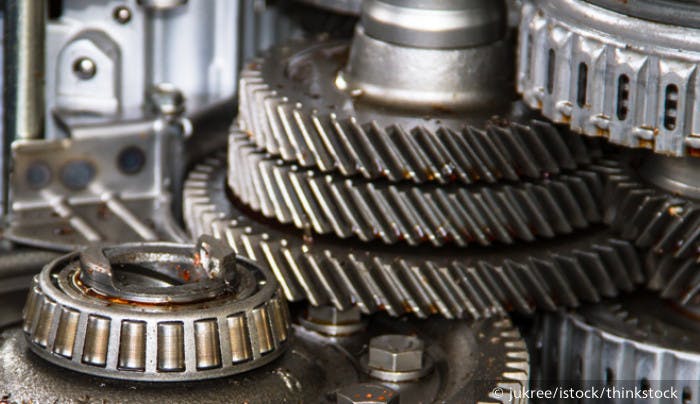

Our PEEK-based VICTREX™ Gear Solutions include gear design, prototyping, testing and manufacturing capabilities using VICTREX HPG™ polymers and help our customers gain a competitive advantage.

Transforming power into motion

Thermoplastic gears - a commercially viable solution for powertrain NVH improvement

Watch to learn all about durability data, NVH performance and cost saving potential.

40+ years of experience in high-precision PEEK gears

Accelerating time to validation

On-site component CAE analysis

On-site tool shop

Consistently meeting industry standards

Managing capacity to meet your demand

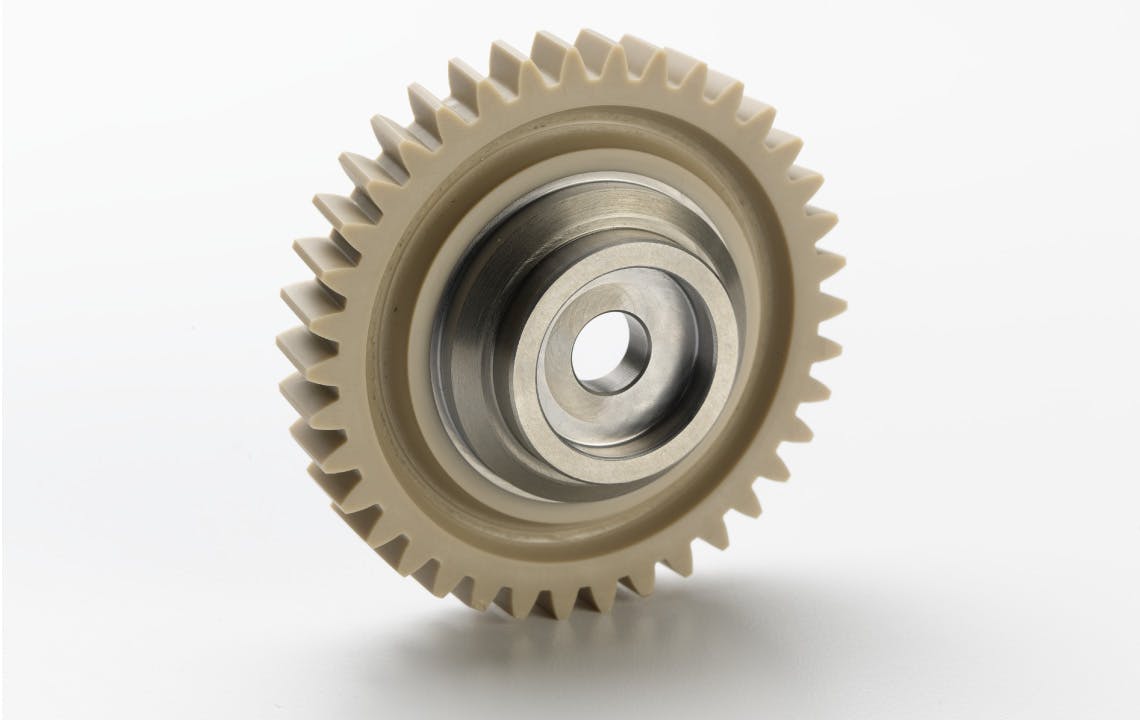

VICTREX HPGTM POLYMER GEARS - A VIABLE AND COST-EFFECTIVE ALTERNATIVE TO METAL GEARS

In efforts of reducing system cost while improving performance, VICTREX HPG gears have been found to offer:

POLYMER GEAR SOLUTIONS THAT GO BEYOND METAL PERFORMANCE

Compared to metal gears, VICTREX HPG™ polymers enable a range of performance benefits:

EFFICIENT AND FAST MANUFACTURING THAT HELPS ACCELERATE YOUR TIME TO THE MARKET

VICTREX HPG gears offer cost-effective, durable NVH in engine and actuation gears with a 360° approach from gear design to mass production.

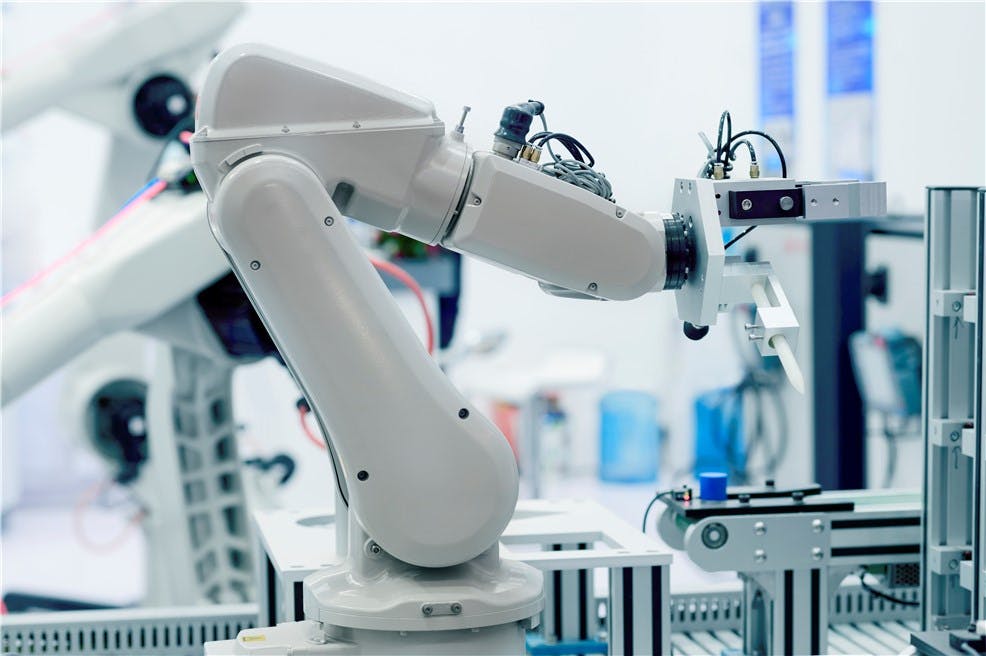

VICTREX HPG™ & thermoplastic hybrid gears offer an alternative to metal planetary system gearboxes. The high precision, tight tolerance and repeatability enables unconstrained cobot engineering design freedom.

Search our products

Tell us what you’re looking for

From the invention of PEEK over 40 years ago, Victrex has continually pioneered new PAEK-based polymers, materials and solutions that have transformed markets, delivering global impact in the toughest environments.

We bring transformational & sustainable solutions that address world material challenges every day.

Hi, do you have PEEK questions I can help with?